Hexagon launched a range of solutions at the Farnborough International Airshow 2024 including a new solution to boost production and increase efficiency by planning and managing factories and shop floors using up-to-date digital twins.

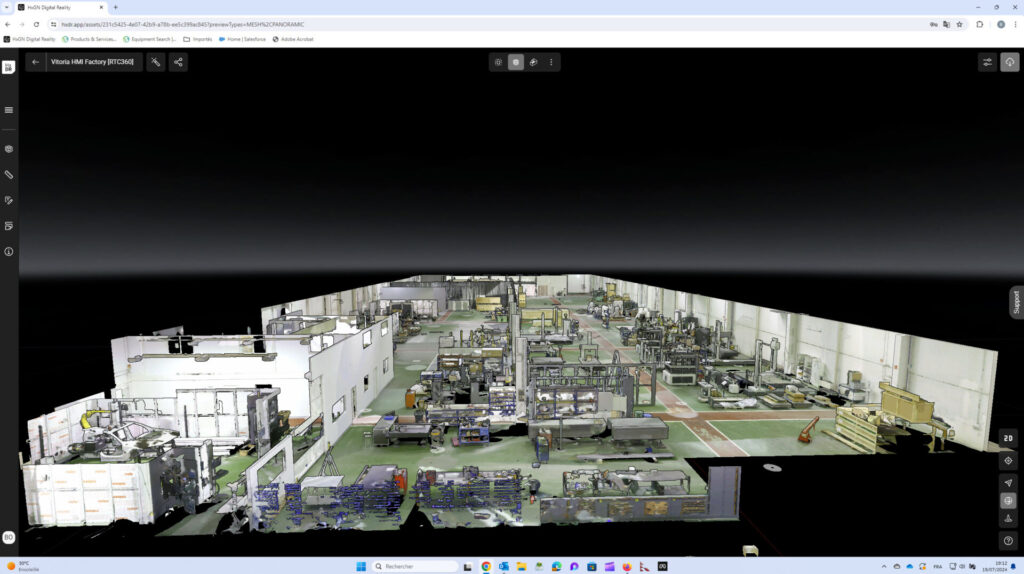

The Digital Factory solution allows production companies to use virtual layouts, workflows, and sites to ensure they are optimised before installation or to improve existing workflows. It can also help companies pivot production lines virtually to test changes to output.

Being cloud-based, Hexagon’s solution can also reduce travel costs for site visits by 50% and on-site staff training.

Nicholas Lachaud Bandres, VP Industry Solutions at Hexagon commented: “Hexagon has developed a deep understanding of manufacturers’ needs. Digital Factory allows to bring the physical world into an accurate virtual sandbox of their factories on-demand. Collaborating with their team and suppliers, they can consider ‘what-if’ scenarios to shape more effective plant designs and layouts and oversee implementation with irrefutable and accessible 3D plans. We’re making the digital factory more affordable and accessible, and we’re excited to see how our customers apply this to ramp up and remain competitive with smarter factories.”

Research carried out by Forrester for Hexagon showed that 32% of manufacturers believe that outdated or ineffective manual processes and workflows are barriers to productivity and collaboration.

By using Digital Factory manufacturers have a future-ready alternative to traditional factory planning enabling them to prevent costly mistakes and make their production lines more efficient. Collaboration is also central to the manufacturing process and Digital Factory allows operations teams from anywhere in the world to work together virtually.